Since the foundation of our predecessor, Technocar Kft, in 1991, the company has built up strong capabilities in all kinds of metal processing and unique know-how to provide with high quality, comprehensive and flexible services to our customers.

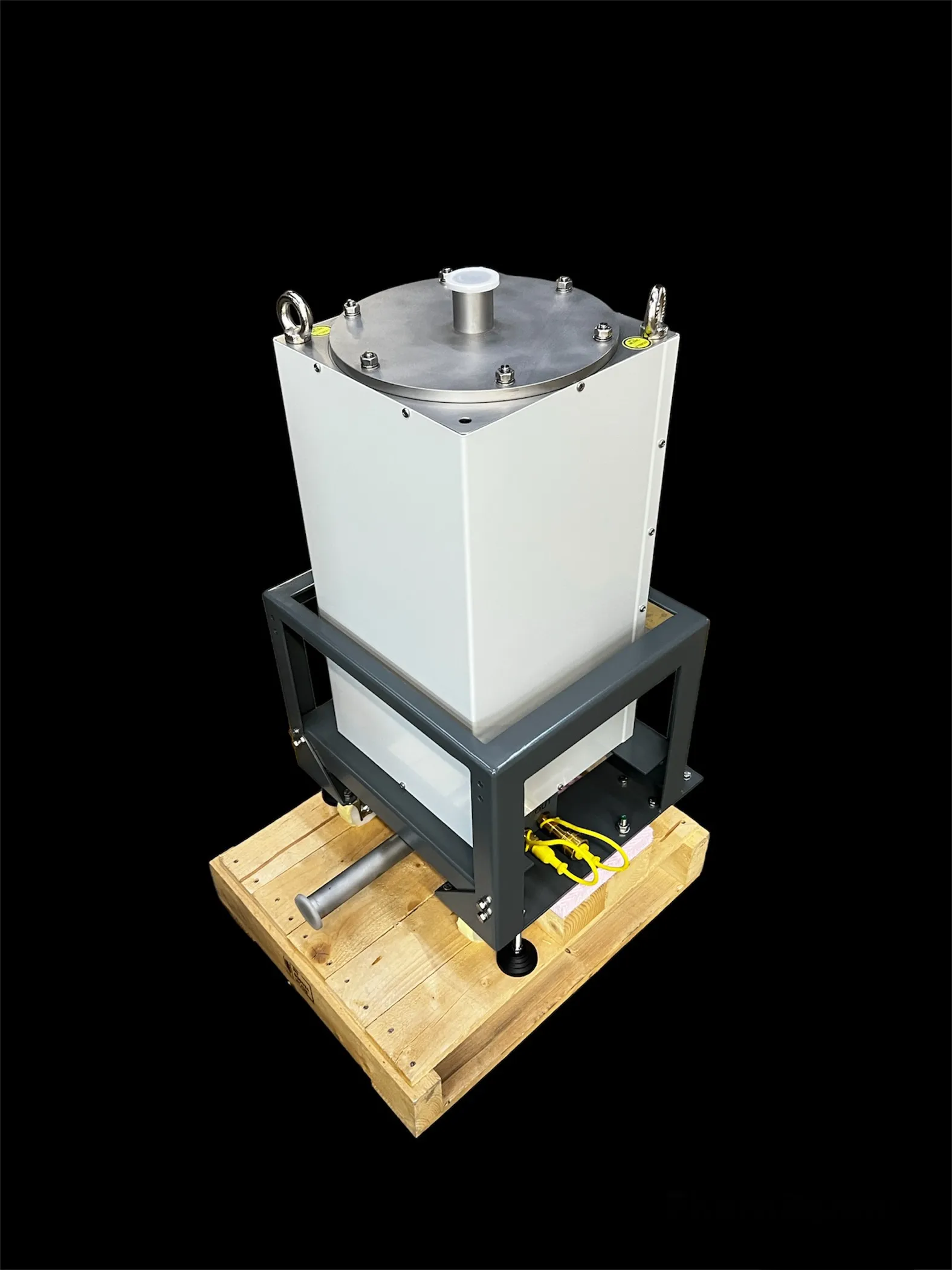

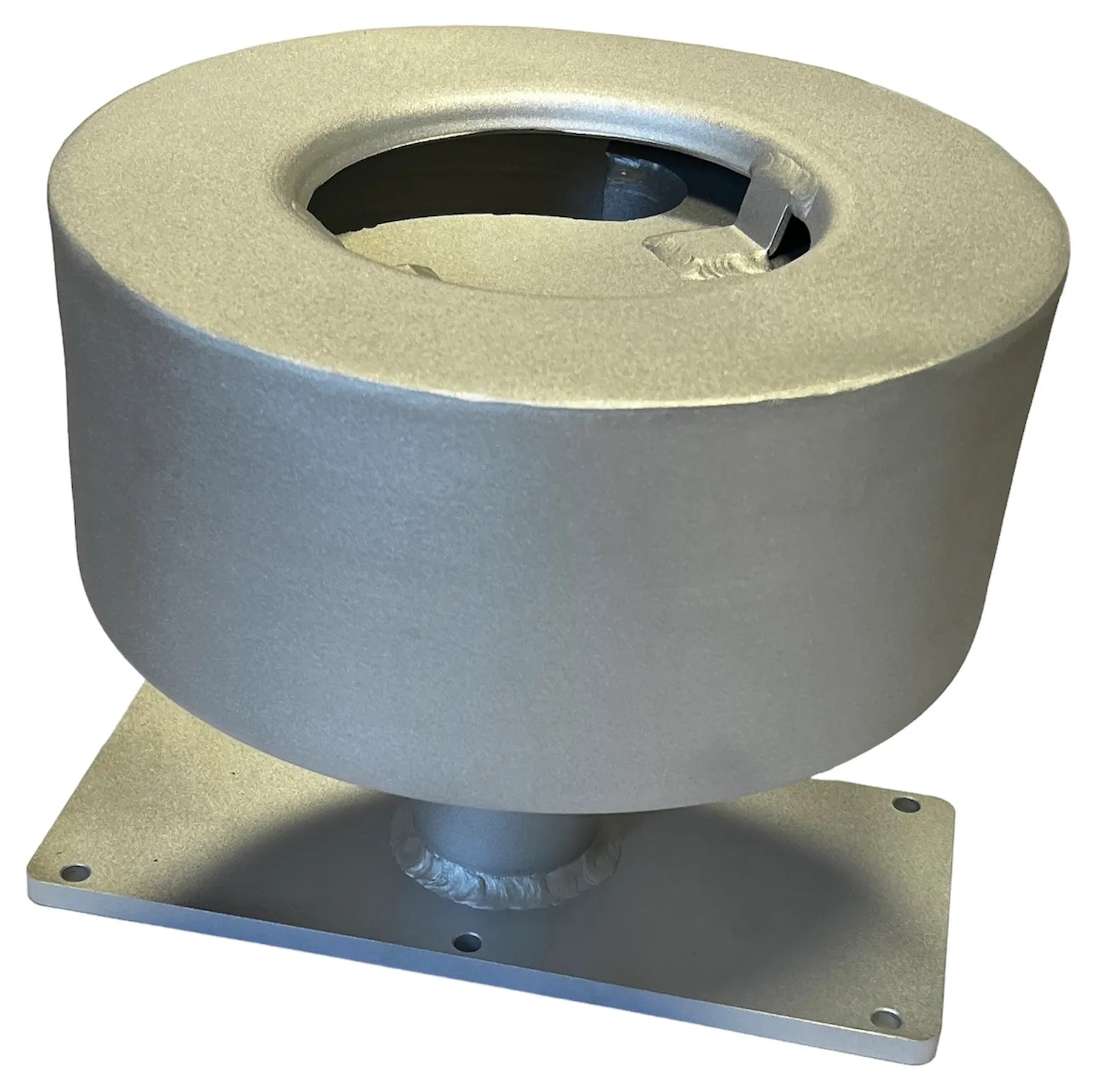

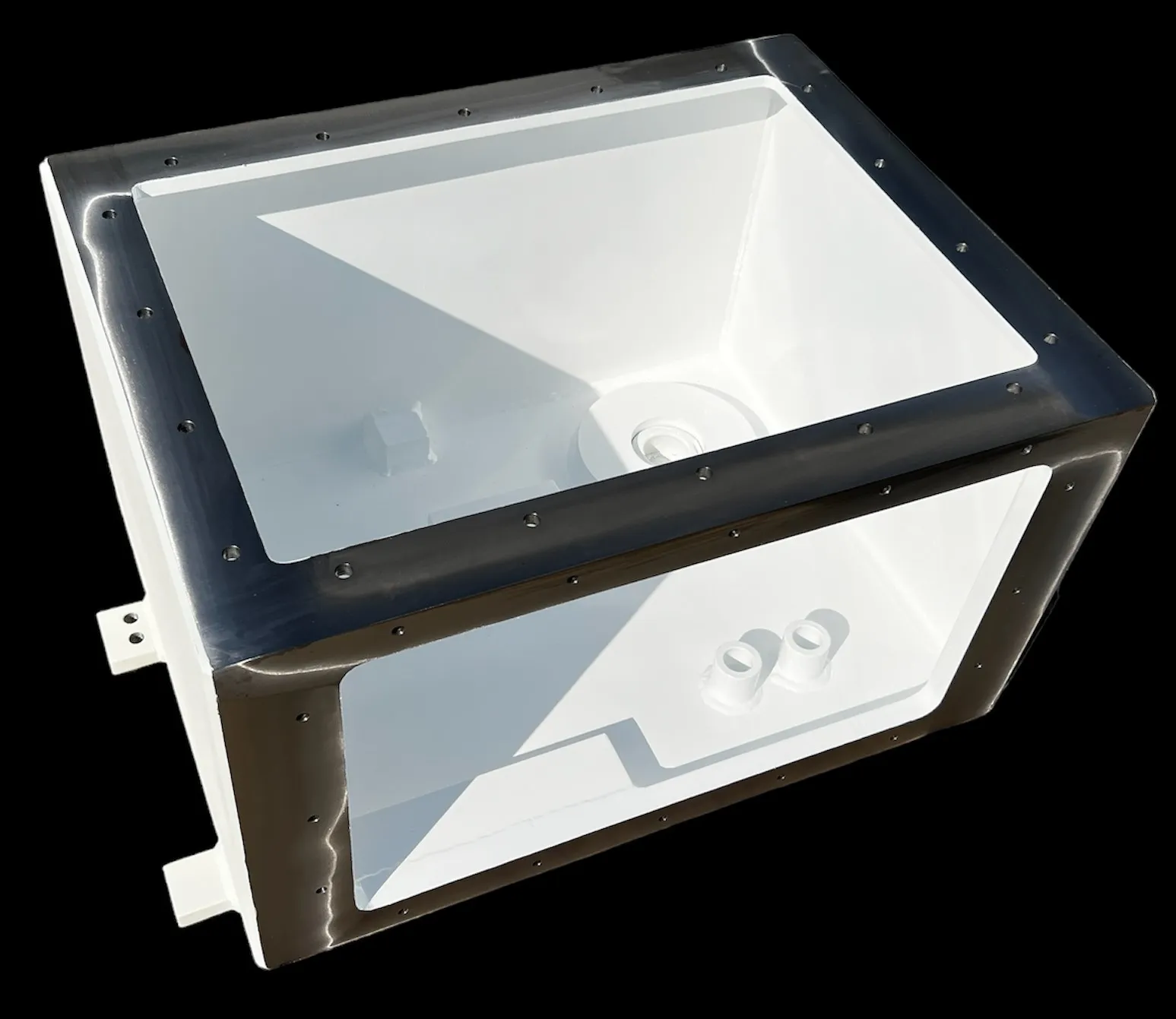

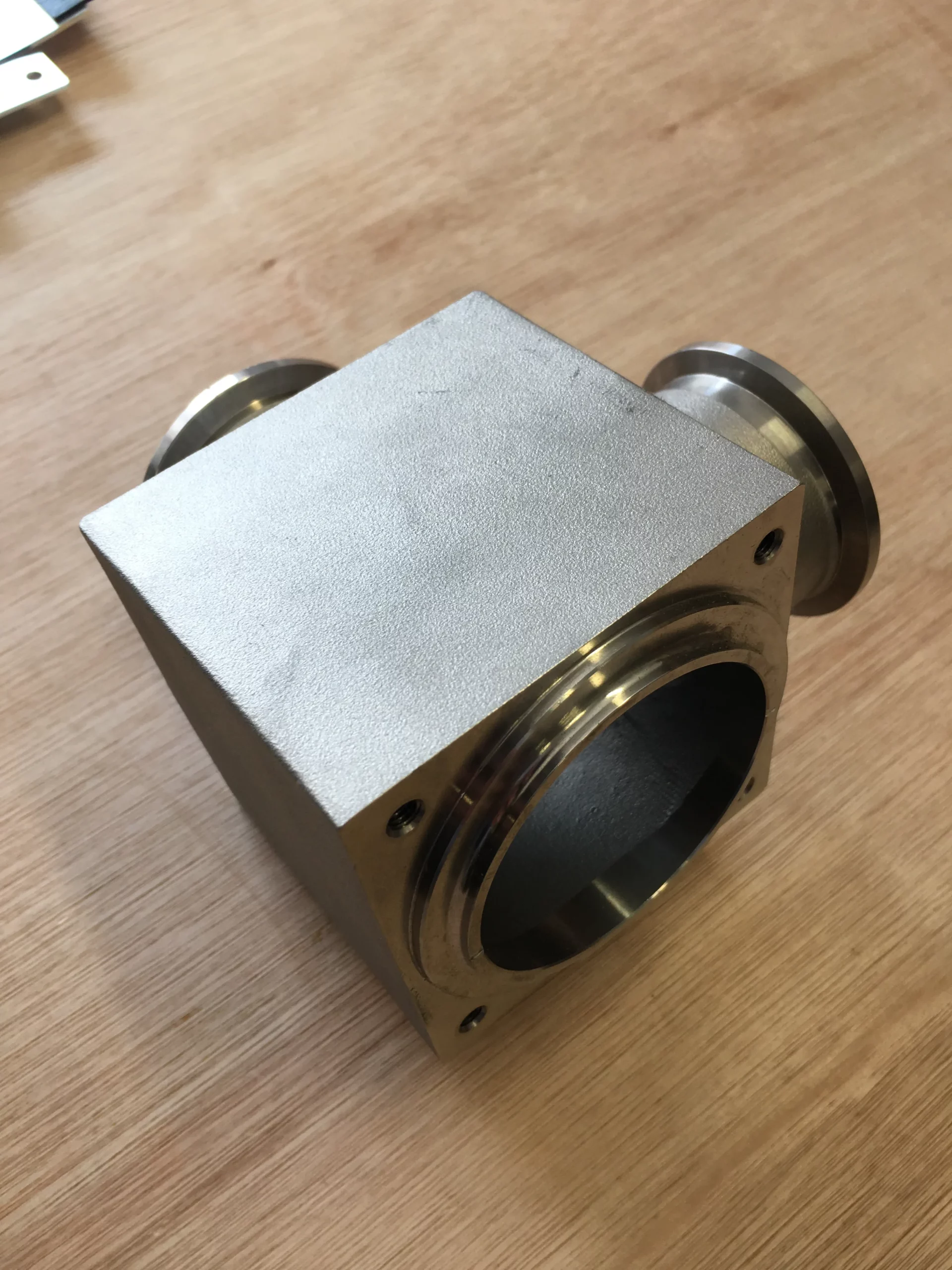

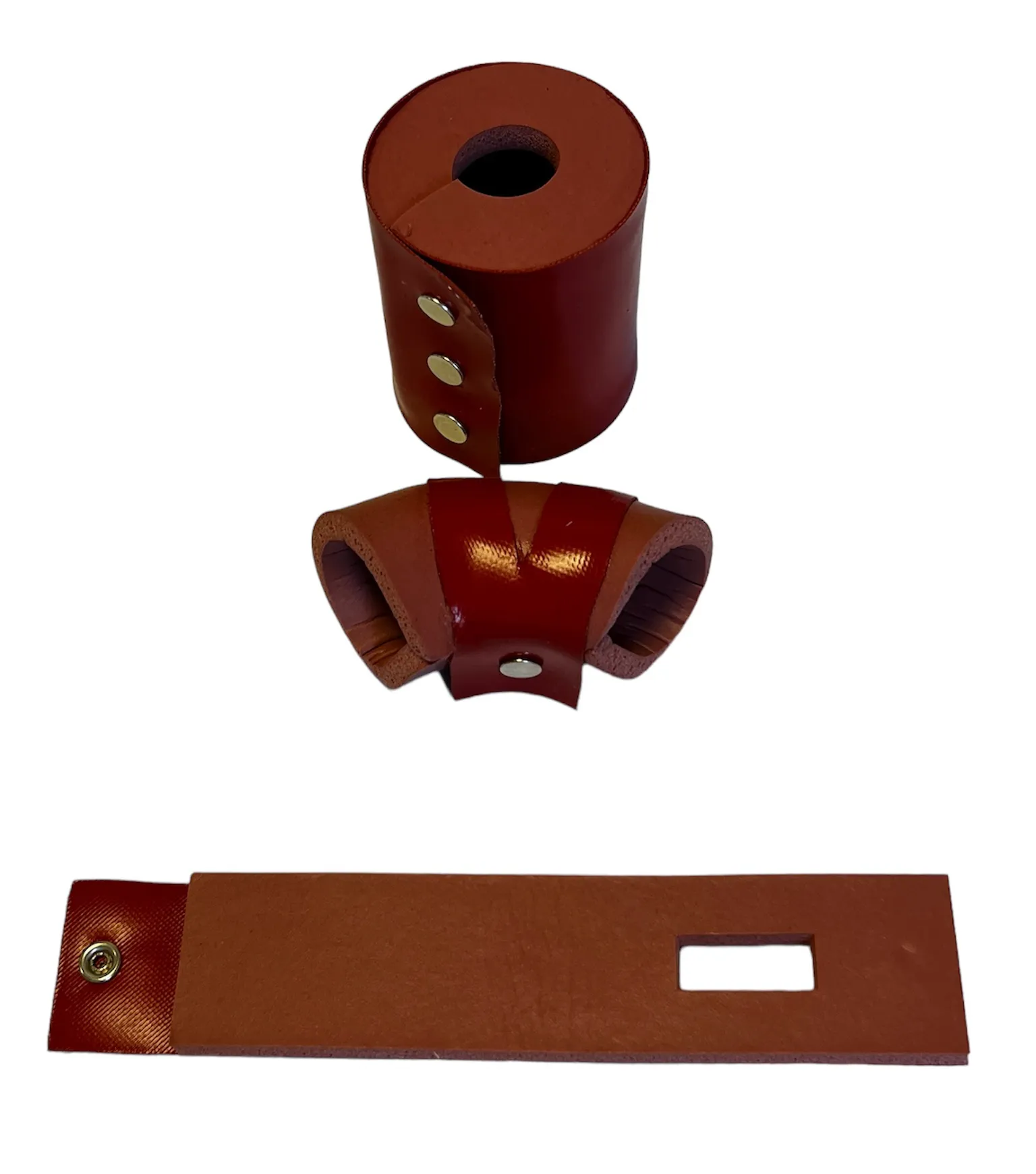

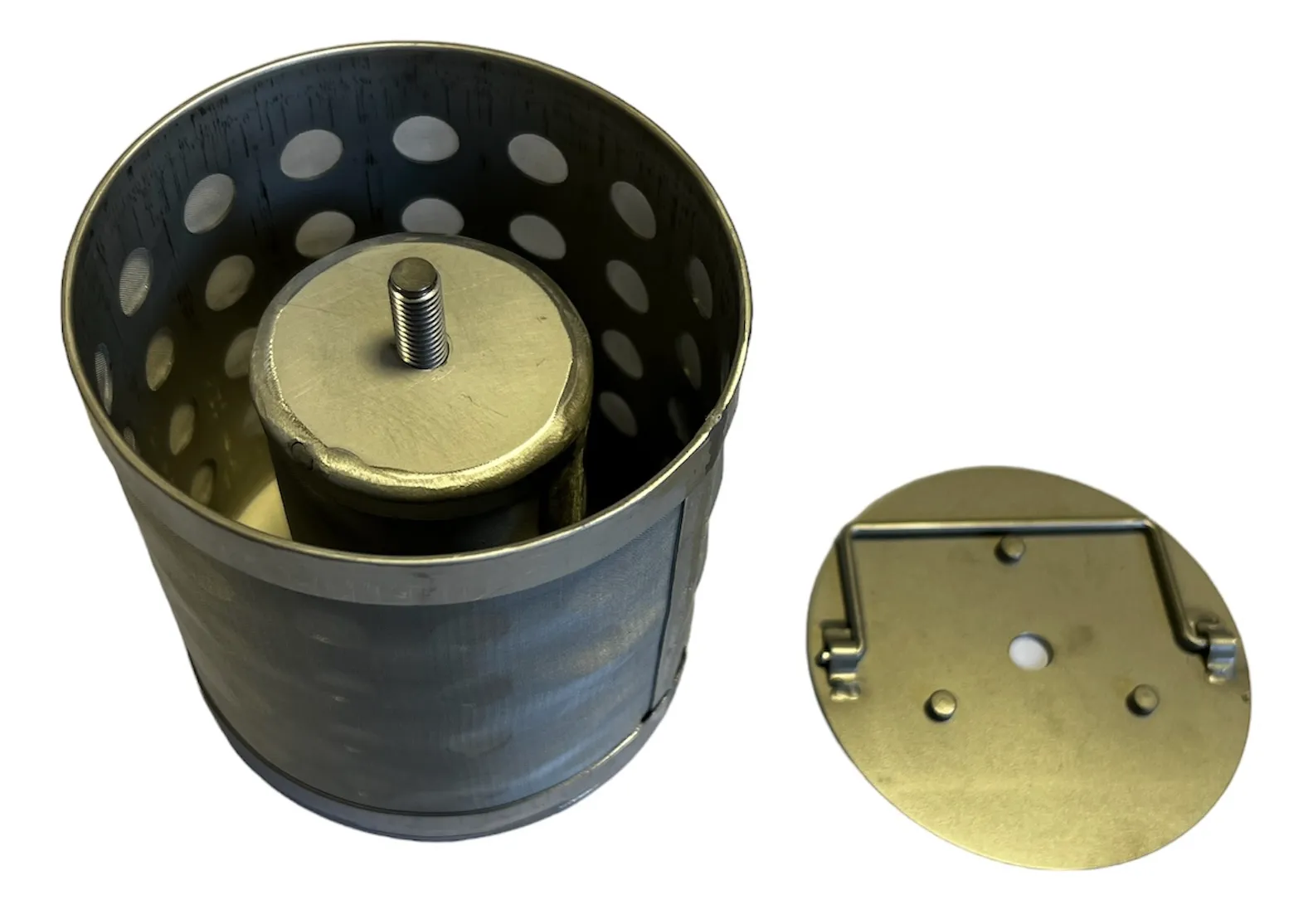

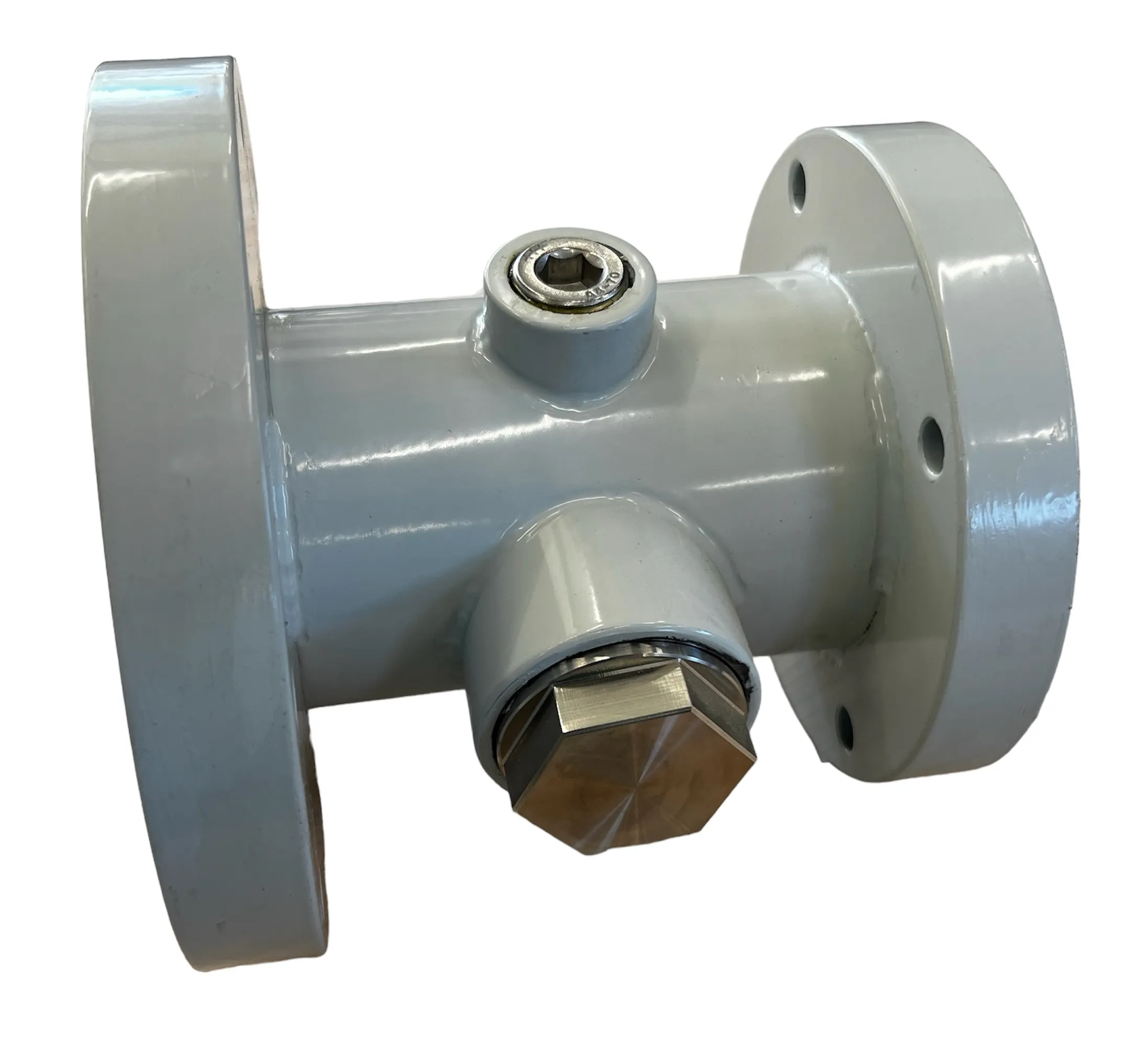

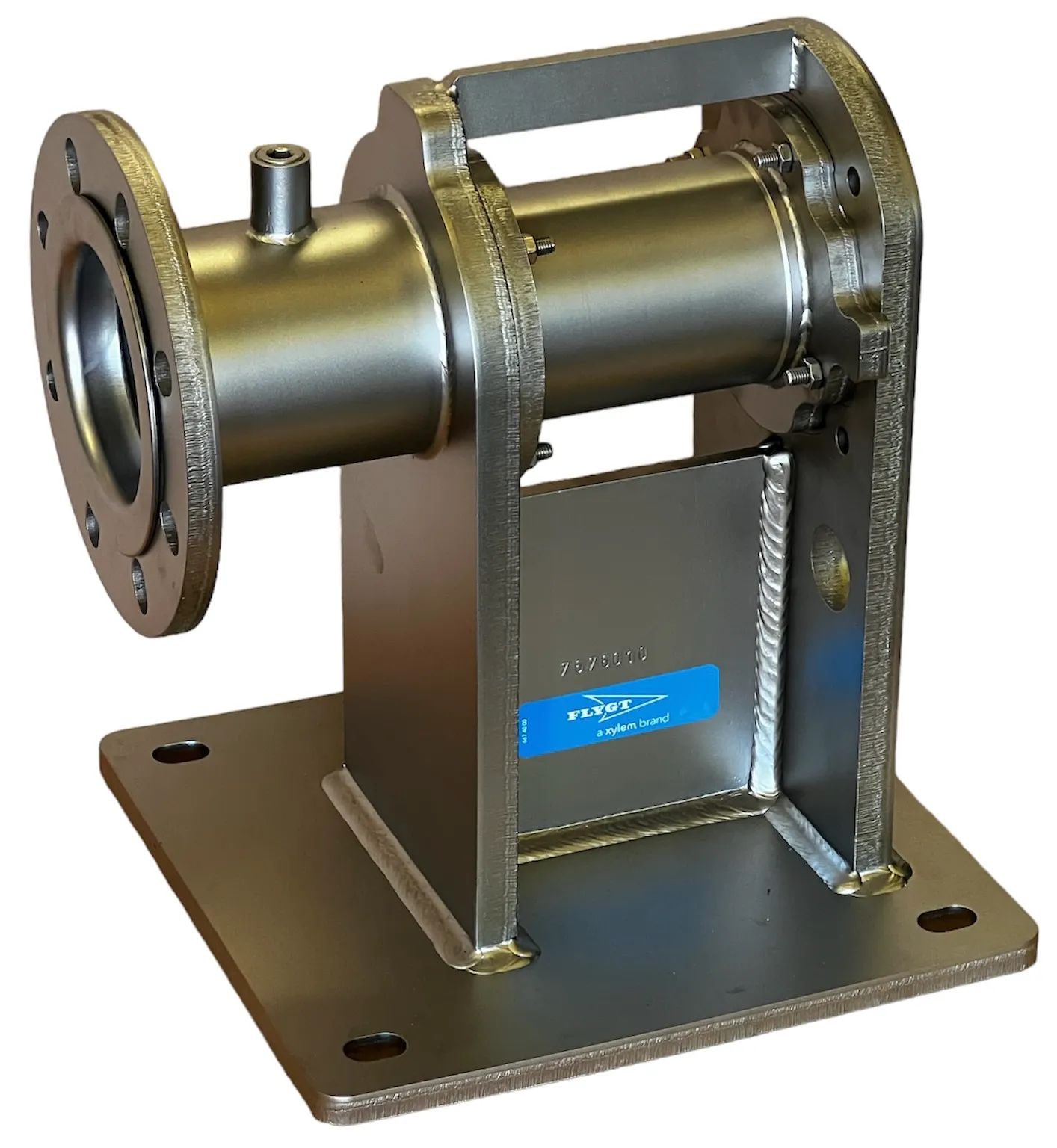

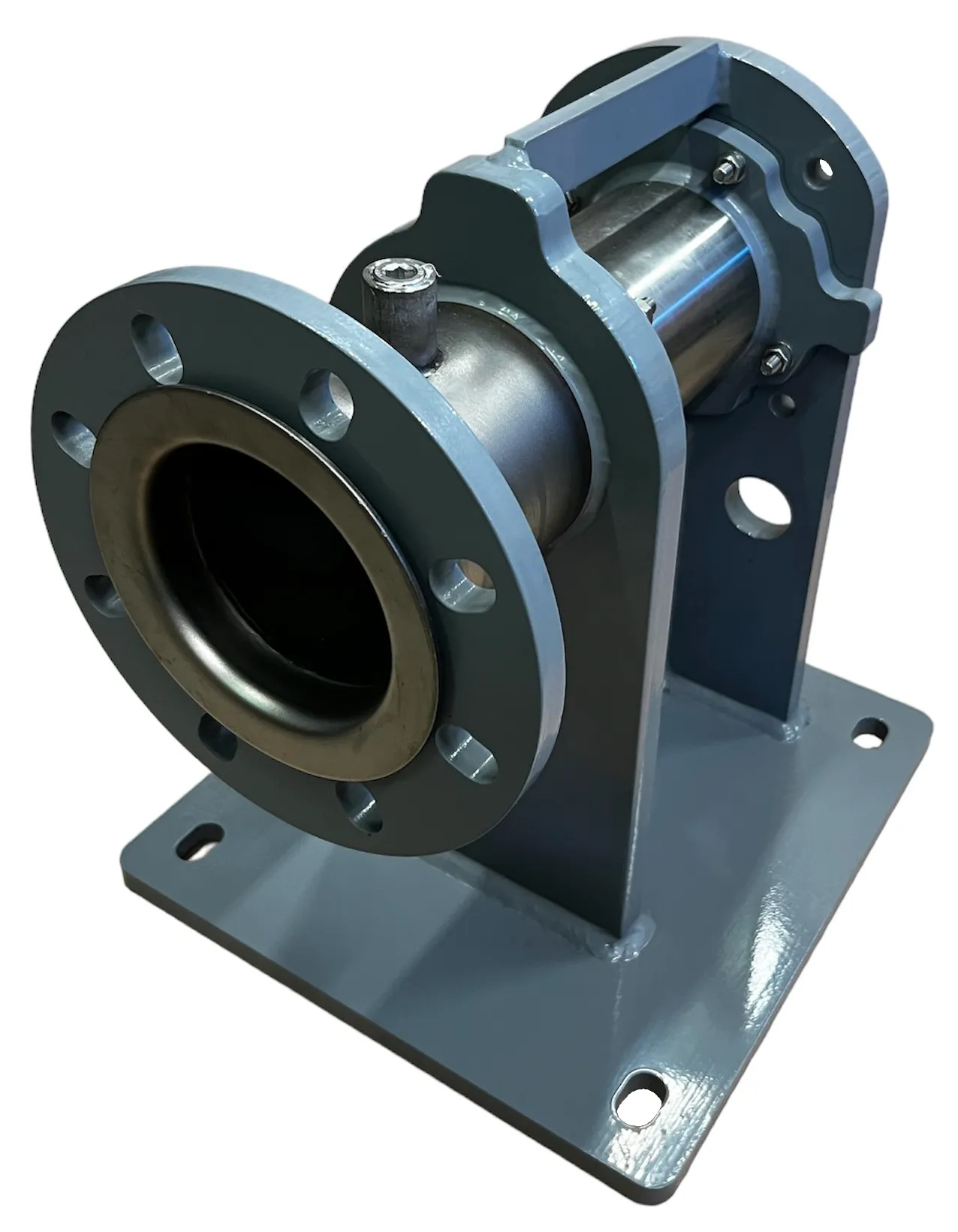

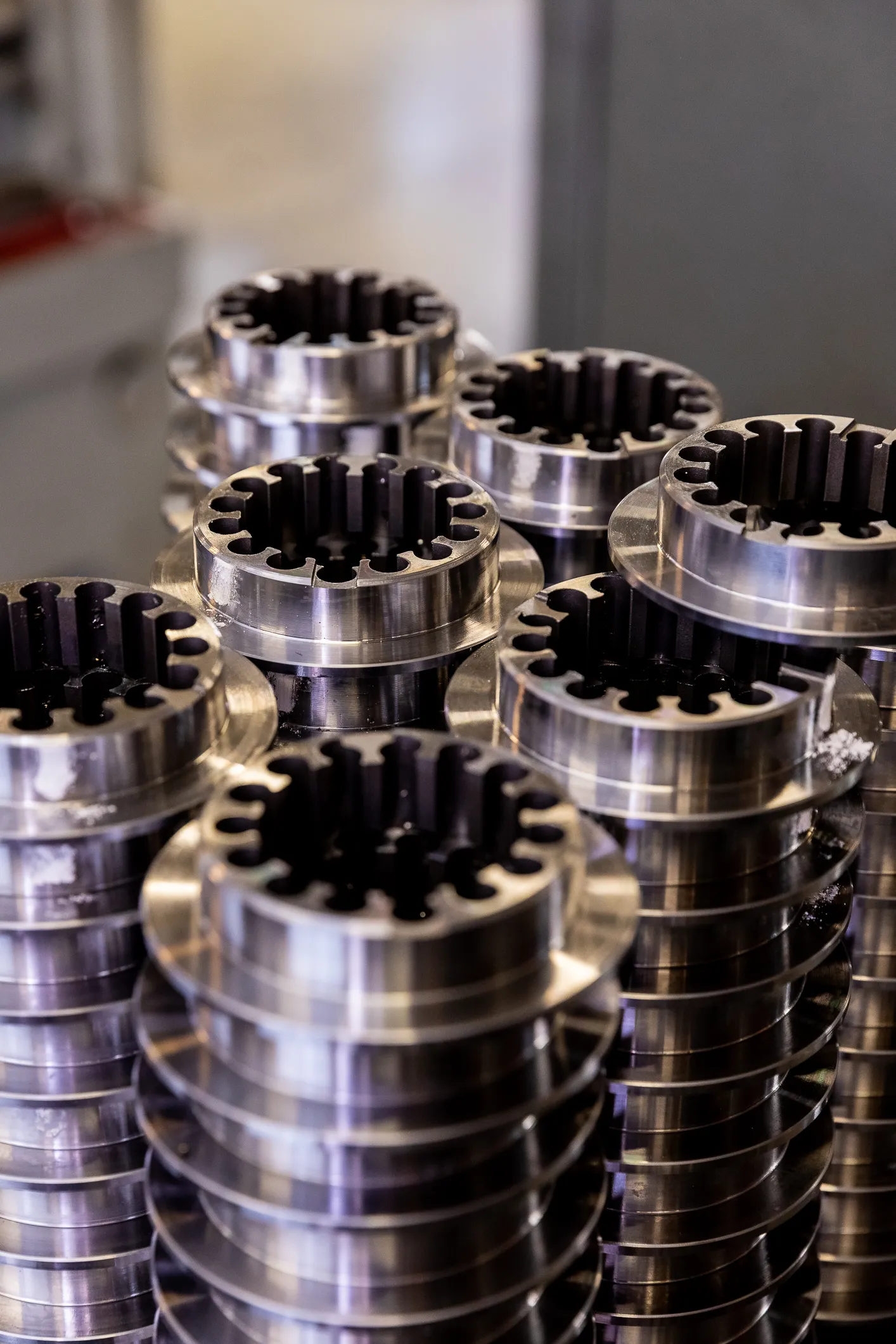

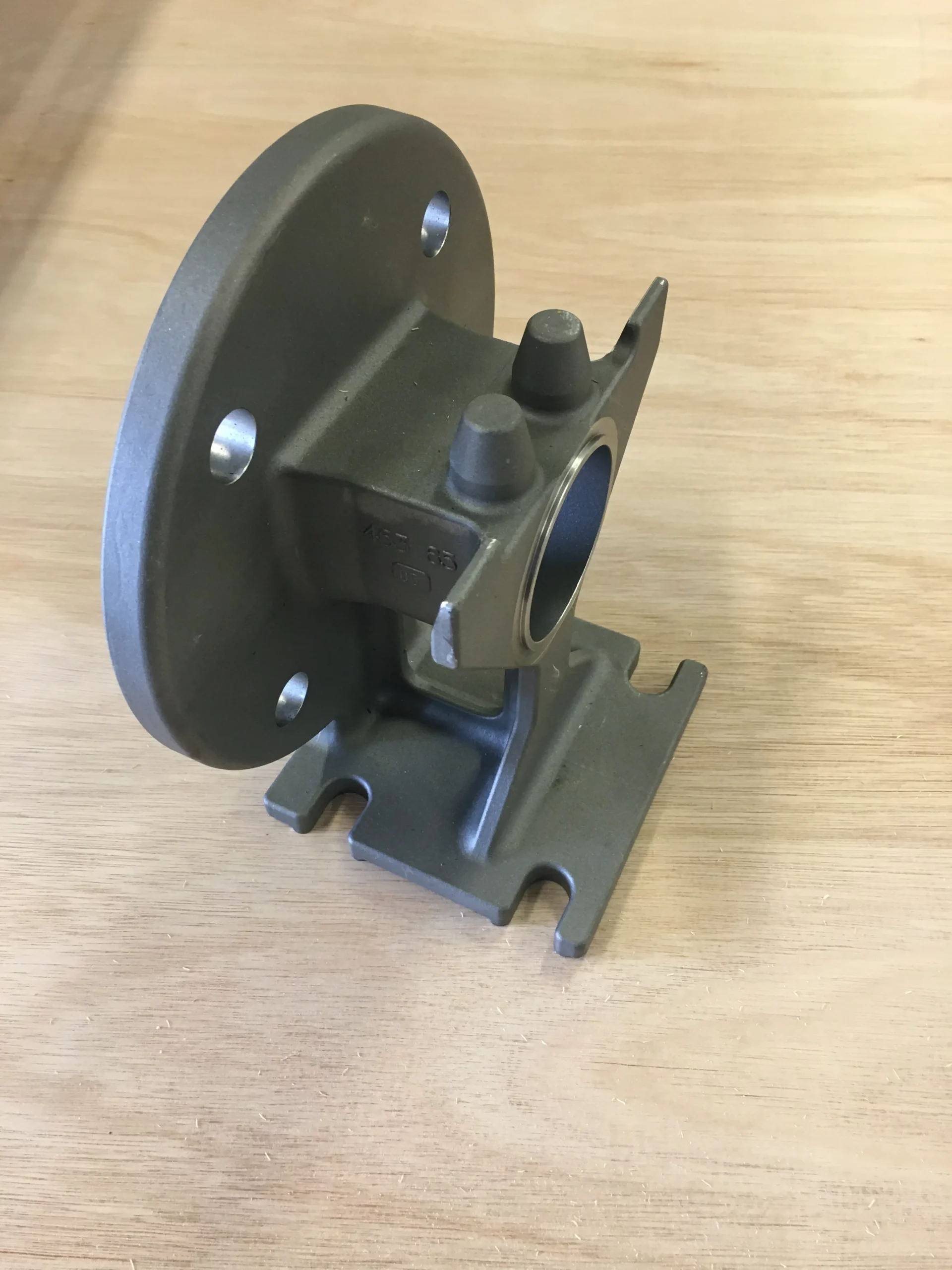

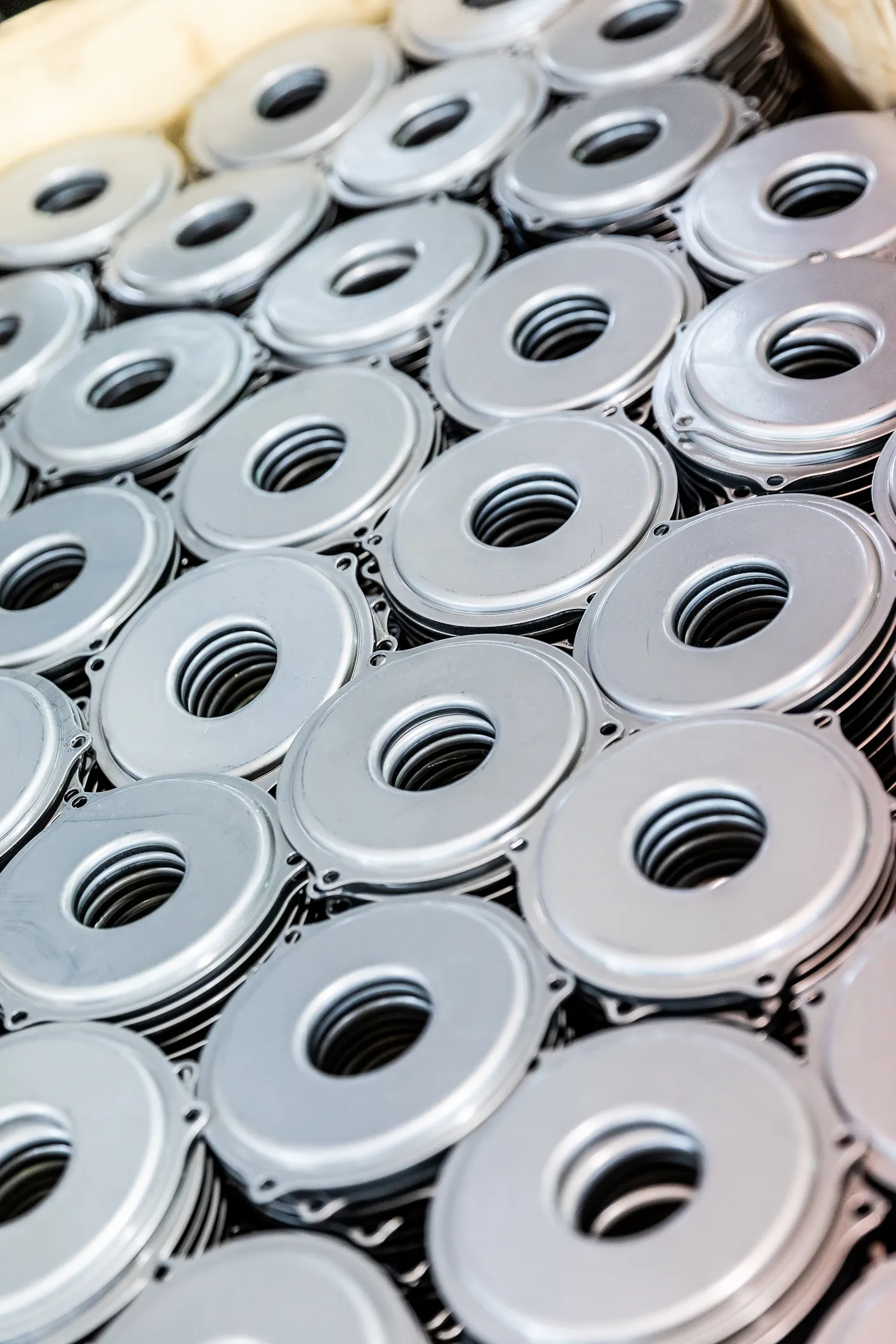

The main activities are CNC and conventional machining, welding (TIG, MIG & LASER/manual and robot), pressing and stamping, sheet metal roll & tube bending, flame-cutting, grit and sand blasting, wet painting, all kinds of sheet metal fabrications. We are familiar with processing most of the metals for industrial use: grey iron, carbon & stainless steel, aluminium, copper & brass, etc.

Technocar has three own sites in Hungary: Bicske, Helvécia and Nagykanizsa. All of them have favourable positions near to highways. The Bicske site, – besides manufacturing -, is also the headquarter of the company and serves as an operation hub. Most of the deliveries to clients are made from Bicske, thus requiring frequent direct in-house transport solutions between Bicske-Helvécia and Bicske-Nagykanizsa.

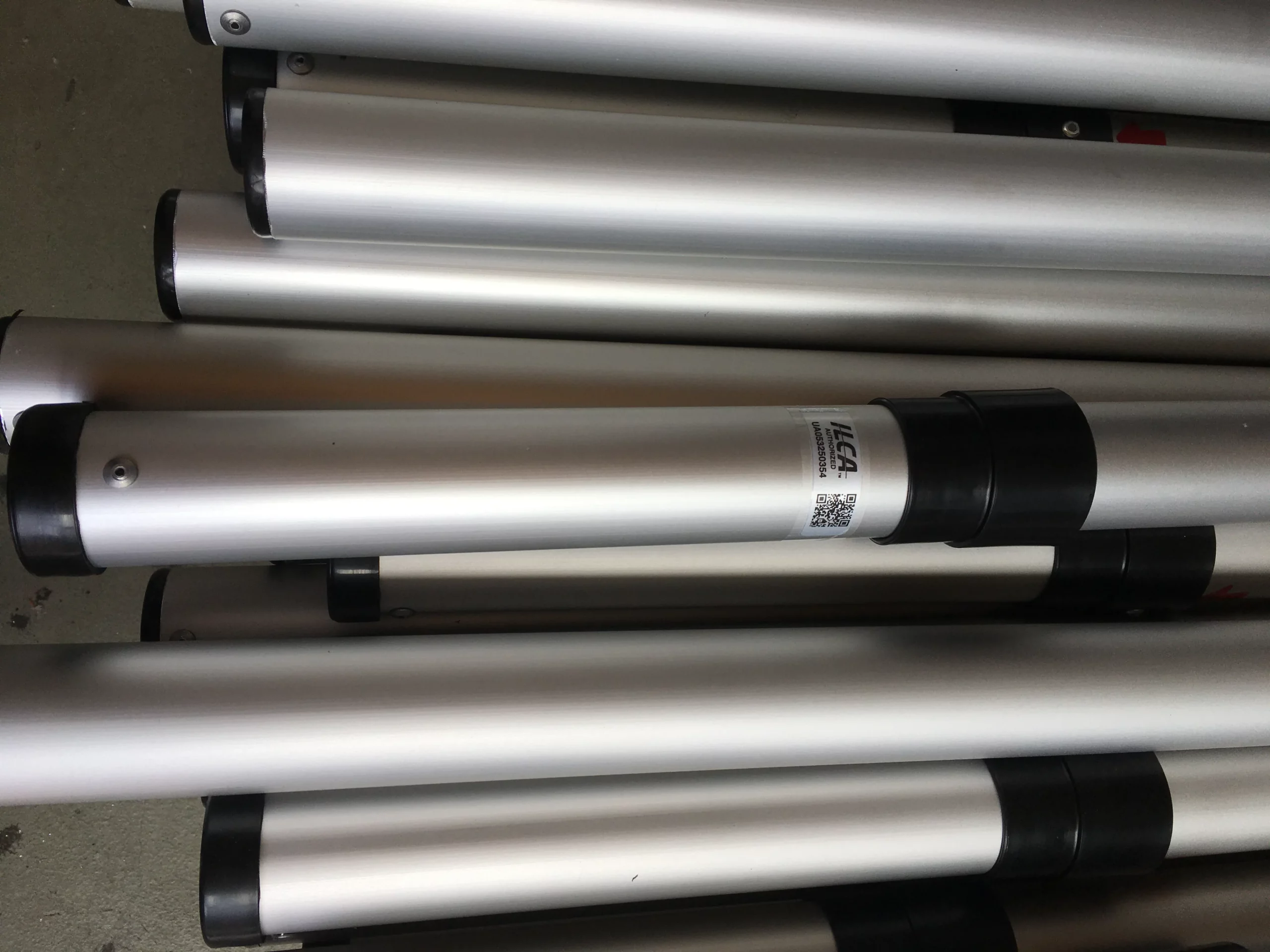

Over 1,500 different, mostly high-precision products (small and medium series) are delivered to different countries all over in the world. Technocar has been focusing to build relationship with clients operating in the developed world. 90% of our net sales have been export all over in our history.

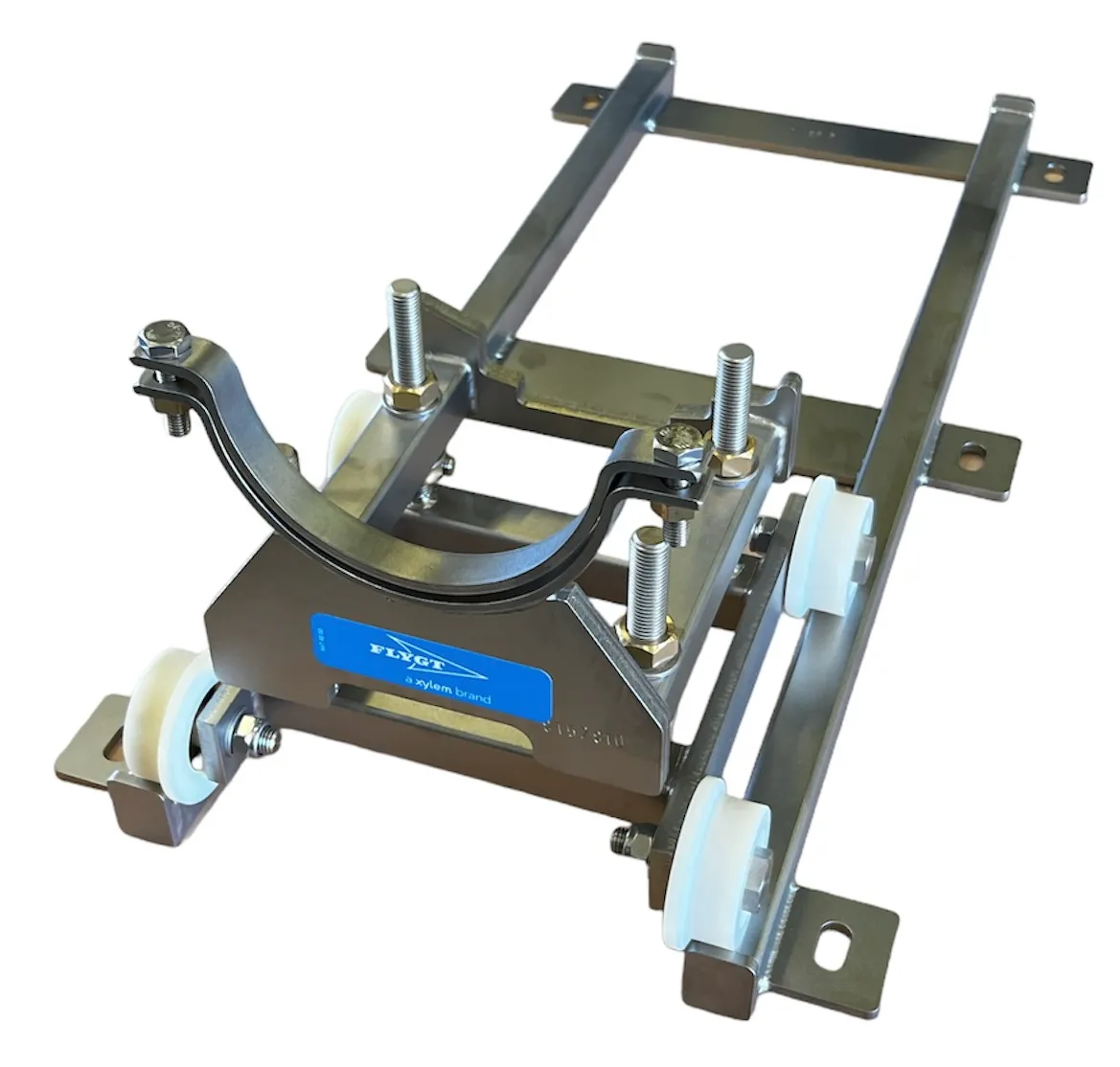

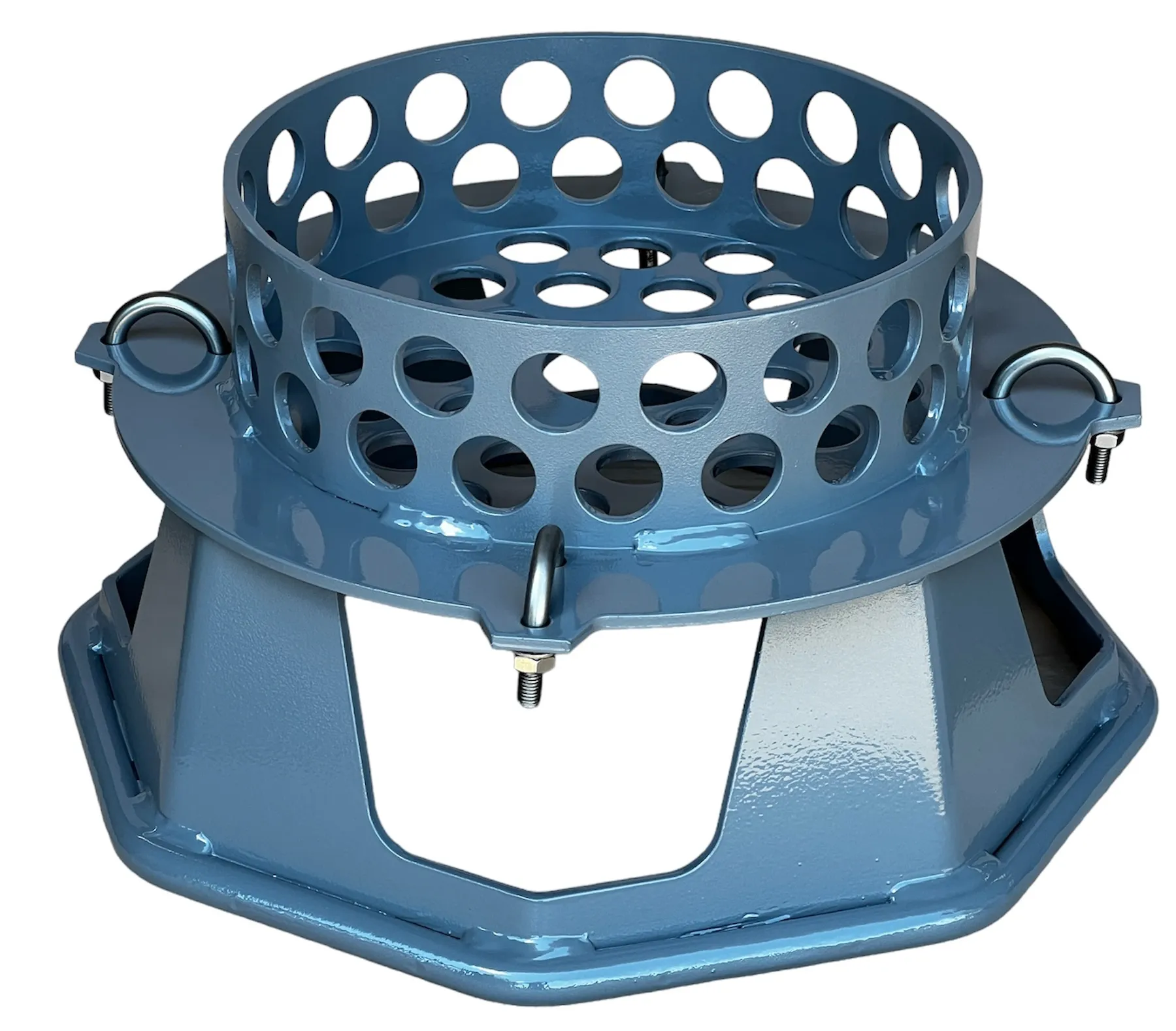

Technocar’s two largest customers are worldwide known, market leader companies, – Xylem and Atlas Copco-, cooperation with them is dated back to decades.

The well diversified product portfolio, – we deliver more than 1,000 products to these two clients -, deliveries on-time and almost zero scrap rates at each client have upgraded Technocar’s positions. We have developed from simple supplier position to partnership in the last ten years.

MANPOWER

person in total

Number of machines

pieces

Product portfolio

types

Qualified suppliers

suppliers

Machining

CNC horizontal, and vertical milling machines, CNC lathes with driven tool holders, Y axis, and counter spindle. Conventional milling machines, and lathes.

Conventional hole, and cylindrical grinding machines.

Welding

MIG / TIG / Laser welding machines with water cooling system for steel, stainless steel and aluminium welding. Rotary tables for large and small parts. Welding robots for high runners. Spot welding capabilities for sheet metal parts.

Painting

Semi automatic painting line with conveyor and

drying chamber, painting chambers for large parts.

Grit blasting

Automatic wheel shotblasting machines, sand and glass bead blasting chambers.

CMM / Scanning

Coordinate measurements and optical scanning of parts to be inspected. Leak testing of critical parts by using special Helium Leak tester

Flame cutting

CNC controlled flame cutting machine is applicable for thick hot rolled sheet metal processing.